Kreuzwertheim/Waltershausen, December 1, 2025

Following the takeover of the business operations of the former ATV Technologie GmbH by Kurtz Ersa Semicon GmbH on September 1, 2025, Kurtz Ersa is now taking the next step in process technologies for microelectronics and microoptics with the takeover of Häcker Automation GmbH by Kurtz Ersa Smart Production GmbH on December 1, 2025. All employees will be retained.

Häcker Automation GmbH, based in Waltershausen near Gotha in Thuringia, has been producing microassembly systems for renowned customers in the semiconductor, electronics, medical technology, and automotive industries for over 30 years with around 50 employees. For example, active alignment units, optical measuring systems with complex evaluation algorithms, and microgrippers are integrated for the laser industry. Areas of application include process modules and turnkey production systems for the manufacture of state-of-the-art lasers, components for medical technology, and miniaturized smart sensors. Automation solutions for the most demanding advanced packaging, inspection, and testing are offered for the manufacture and processing of semiconductors.

After successful takeover (from left): Massimo De Vivo – Head of Human Resources at Kurtz Ersa, Hubert Baren – Managing Director of Kurtz Ersa Automation GmbH, Gerrit Häcker – Managing Director with a stake in Kurtz Ersa Smart Production, Thomas Mühleck – CEO of Kurtz Ersa, Christian Diehm – Head of Finance at Kurtz Ersa, Vincent Kurtz – Manager of Global Operations and Transformation at Kurtz Ersa

These solutions help to increase performance and thus reduce the power consumption and costs of new digital products. The process expertise for all these applications lies in automated cells and tools for assembly, dispensing, soldering, measuring, alignment, optical calibration, and joining, as well as the associated conveyor technology, and thus fits perfectly with Kurtz Ersa´s vision: The No.1 team for sustainable production solutions.

“We are delighted to have found another building block for our buy & build strategy in the semiconductor and microelectronics sector with Häcker Automation. We were immediately impressed by the technology and are pleased to have Gerrit Häcker on board as Managing Director with a stake in the company. Our global sales and service network with production facilities around the world has already embraced the new product portfolio, enabling us to scale the business together with Gerrit Häcker,” says Thomas Mühleck, CEO of Kurtz Ersa.

“With the acquisition of Häcker Automation GmbH by Kurtz Ersa and the merger into the new Kurtz Ersa Smart Production GmbH, important competencies are being combined to sustainably advance our globally leading microassembly platform as a future-proof production technology for microtechnology. Our customers will soon benefit from a host of useful synergies,” comments Gerrit Häcker, founder of Häcker Automation GmbH and Managing Director and co-partner of the new Kurtz Ersa Smart Production GmbH.

“The high degree of standardization and the modularity of Häcker Automation´s modular system enable us to offer the right solutions in a growth market and to scale up quickly in our plants in the triad if necessary. This technology – combined with the global strength of the Kurtz Ersa Group – is a win-win situation for both companies and a strategic step into the future for Kurtz Ersa,” adds Hubert Baren, CEO of Kurtz Ersa Automation.

Constant support and transparency in the realization of your projects right from the start. – That is what we offer you as a solution partner.

No matter in which phase of your project you address a topic to us, our team guarantees you comprehensive support and always the right answers to your questions.

Find out more about the possibilities of our cooperation and benefit from extensive materials about your machine project.

The open and modular machine platform is the perfect tool for realising your extensive processes.

Electrical, mechanical and software interfaces enable easy connection of processing heads and modules.

Thanks to optional trolley system you can increase the flexibility and versatility.

Common knowledge increases quality, creates an inexhaustible variety of products and offers many opportunities for adding value.

Do you have questions about open source or another topic that we haven't answered yet? Here you can get in touch with our Automation Team.

OurPlant Smart Tools

is the modular solution for developing your micro-assembly processes.

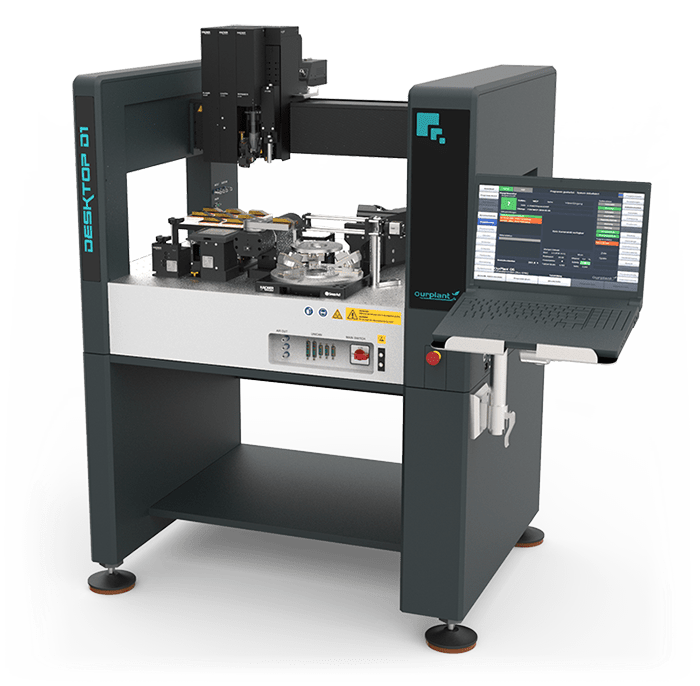

The desktop machine OurPlant D1 is the basis for the seamless transition of your products

into series production.

The modular design of the OurPlant XTec guarantees adaptation to individual and rapidly changing process requirements.

Like all micro assembly machines of OurPlant, the OurPlant X3 blue is based on a modular design.

Do you need information on a specific topic? Or do you have an individual question? Then do not hesitate to contact us.

Um dir ein optimales Erlebnis zu bieten, verwenden wir Technologien wie Cookies, um Geräteinformationen zu speichern und/oder darauf zuzugreifen. Wenn du diesen Technologien zustimmst, können wir Daten wie das Surfverhalten oder eindeutige IDs auf dieser Website verarbeiten. Wenn du deine Zustimmung nicht erteilst oder zurückziehst, können bestimmte Merkmale und Funktionen beeinträchtigt werden.