Quality. Precision. Automation.

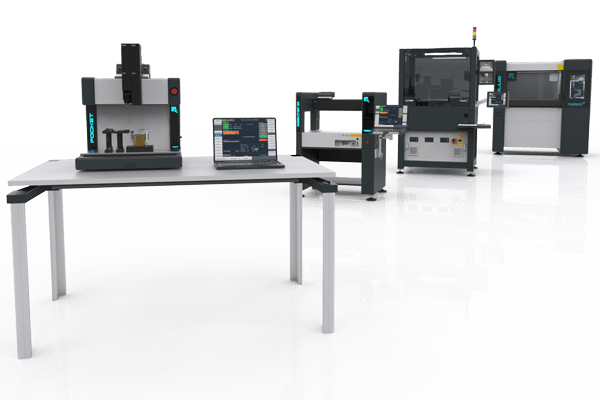

Ziel des Projektes ist es, ein hochmodulares System zu entwickeln, das herstellerübergreifend Komponenten miteinander verbindet und interagiert.

Es soll eine Architektur realisiert werden, die auf Microservices und dem Clustering dieser Zellen basiert. Um dieses Ziel zu erreichen, müssen innovative und Industrie 4.0-konforme, echtzeitfähige und ereignisgesteuerte Kommunikationstechnologien ausgewählt und integriert werden.

Diese Ansätze neigen dazu, das System inkonsistent und angreifbar zu machen. Um dem entgegenzuwirken, müssen Technologien integriert werden, die das System robust und zuverlässig machen und vor Cyberangriffen schützen. Für die gemeinsame herstellerübergreifende Integration von Komponenten ist eine enge Zusammenarbeit mit unseren Partnern und eine Standardisierung der Ergebnisse notwendig.

Häcker Automation wird prototypisch zeigen, dass neu entwickelte Produktionsprozesse auf verschiedenen Produktionsanlagen mit Komponenten unserer Partner ablaufen können.

01.03.2017 – 29.02.2020 (3 Jahre)

Bundesministeriums für Wirtschaft und Energie (BMWi)

Förderprogramm PAiCE

Projektträger

Deutsches Zentrum für Luft- und Raumfahrt e.V. (DLR)

Kooperationspartner

Kontakt

Dipl.-Inf. Ulf Böttner-Common

Kurzbeschreibung

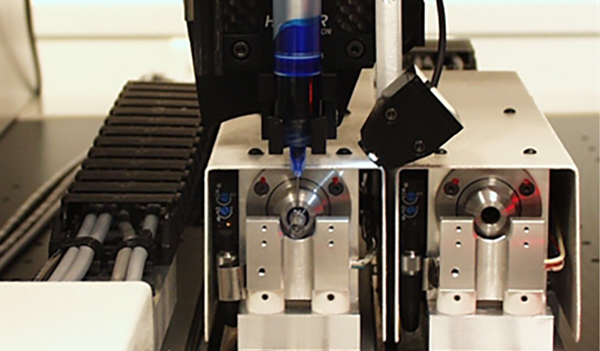

Werkzeugmaschinen verfügen nicht über ausreichende Intelligenz für eine konsequent autonome Produktion. Für die autonome Produktion ist eine Prozessüberwachung erforderlich, aber es gibt keine geeigneten eingebetteten Sensorsysteme.

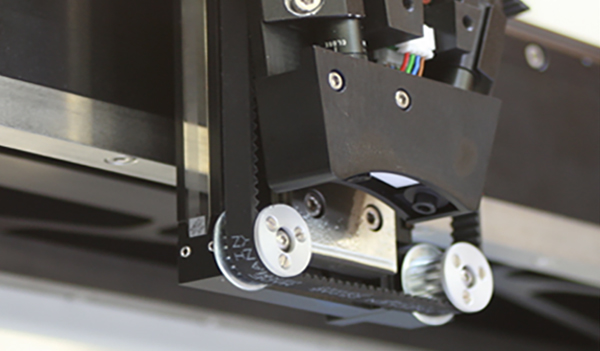

Aktuelle Prozessüberwachungssysteme bestehen oft aus mehreren Komponenten, sind schwer in die Maschine zu integrieren, nicht echtzeitfähig und teuer. Ziel des Projektes ist es, die Intelligenz von Werkzeugmaschinen durch die Integration eines eingebetteten Multisensorsystems in die Werkzeughalterwanne zu erhöhen:

Miniaturisierung, durch konsequente Nutzung von 3D-Elektronik

Autonom, durch drahtlose Energieübertragung zum Werkzeughalter

Dezentralisierung, da automatische Signalanalyse am Entstehungsort

Eine integrierte Datenverarbeitung in der Werkzeugaufnahme, die direkt Prozessinformationen für die Maschine erzeugt. Das System legt den Grundstein für die Prozessüberwachung und -steuerung in einer intelligenten Werkzeugmaschine.

Bundesministerium für Bildung und Forschung (BMBF)

Kooperationspartner

Kontakt

Dipl.-Ing. Christian Schiek

Karlsruher Institut für Technologie (KIT / PTKA-PFT)

Bundesministerium für Bildung und Forschung (BMBF)

Kooperationspartner

Kontakt

Dr.-Ing. Max Körner

Bundesministerium für Bildung und Forschung (BMBF)

Kooperationspartner

Kontakt

Dr.-Ing. Max Körner

Um dir ein optimales Erlebnis zu bieten, verwenden wir Technologien wie Cookies, um Geräteinformationen zu speichern und/oder darauf zuzugreifen. Wenn du diesen Technologien zustimmst, können wir Daten wie das Surfverhalten oder eindeutige IDs auf dieser Website verarbeiten. Wenn du deine Zustimmung nicht erteilst oder zurückziehst, können bestimmte Merkmale und Funktionen beeinträchtigt werden.