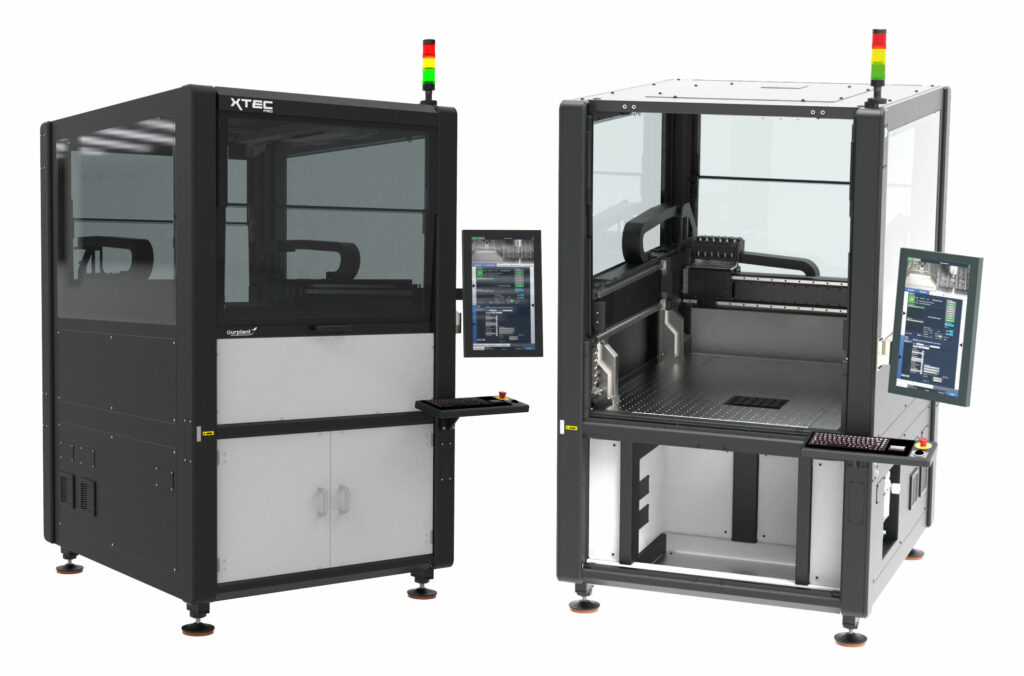

Meet complex or constantly changing process requirements with a freely configurable machine.

The generously and individually customizable interior of the OurPlant XTec Pro, with additional cutouts in the front machine area, provides you with space for equipment such as collimators, control and supply devices, as well as AOI and feeding systems.

In addition, the geometry of the base plate in the functional area can be freely designed.

“Digitization will produce winners faster than the losers know they are losers,” warns Prof. Frank Piller of RWTH Aachen University. There are still enough people who don’t want to take the fourth industrial revolution seriously enough.

And so I have just returned from a research trip to Switzerland. Once again, many new digital achievements were launched as part of the relevant research projects and German industry associations. All really spectacular. “All we have to do now is find someone who has a real problem with it,” I can still hear the VDMA officer saying.

Do you need information on a specific topic? Or do you have an individual question? Then do not hesitate to contact us.

Um dir ein optimales Erlebnis zu bieten, verwenden wir Technologien wie Cookies, um Geräteinformationen zu speichern und/oder darauf zuzugreifen. Wenn du diesen Technologien zustimmst, können wir Daten wie das Surfverhalten oder eindeutige IDs auf dieser Website verarbeiten. Wenn du deine Zustimmung nicht erteilst oder zurückziehst, können bestimmte Merkmale und Funktionen beeinträchtigt werden.