In addition to software sources, design data, interfaces of all kinds, this includes specialist knowledge from the areas of development, production, application and support. The data are open to everyone.

Häcker Automation stands for trusting cooperation on an equal footing! Our understanding: Common knowledge increases quality, creates an inexhaustible variety of products and offers a wide range of value creation opportunities. In the future you will benefit from a steadily growing pool of information and interactive offers.

“Digitization will produce winners faster than the losers know they are losers,” warns Prof. Frank Piller of RWTH Aachen University. There are still enough people who don’t want to take the fourth industrial revolution seriously enough.

And so I have just returned from a research trip to Switzerland. Once again, many new digital achievements were launched as part of the relevant research projects and German industry associations. All really spectacular. “All we have to do now is find someone who has a real problem with it,” I can still hear the VDMA officer saying.

German mechanical engineering goes digital. So the question arises as to whether, with all the great digital solutions and offerings, we haven’t already reached the goal of future-proof mechanical engineering? The simple answer is: “NO, not at all!”.

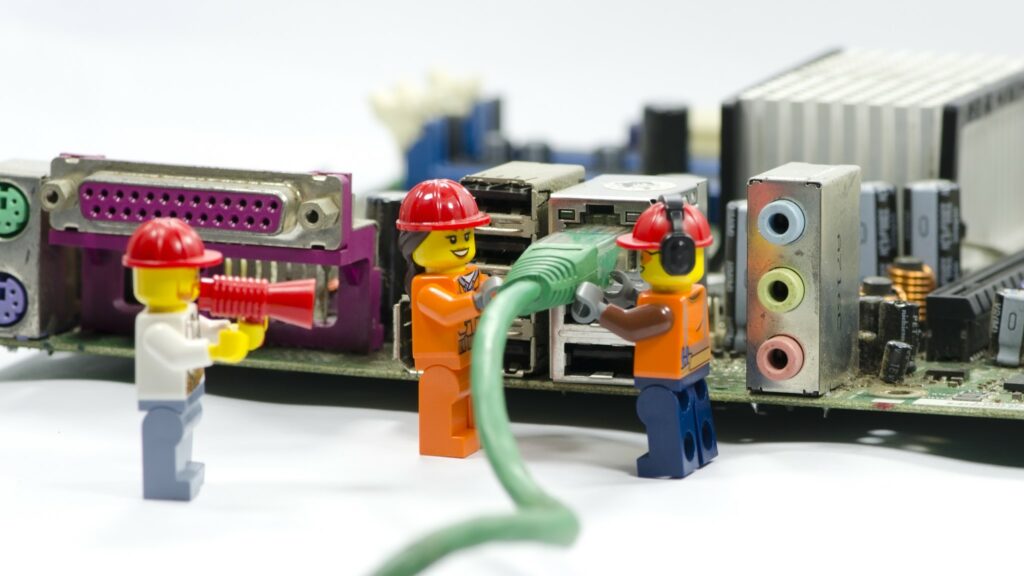

If we want to move mechanical engineering in Central Europe into the fourth industrial age together, we can learn a lot from LEGO style. You want to know HOW? Feel free to check out our video podcast on the topic.

Gerrit Häcker, Managing Director of Häcker Automation GmbH

There is no alternative to the high-precision manufacturing systems from Häcker Automation when it comes to automating complex and multi-layered processes. A perfectly tailored model is available for every phase of your process.

Do you want to move your product from the test stage to production? – No problem! Thanks to standardized interfaces, independent function modules and easy configuration of the systems, adaptation to changing requirements is easily possible.

The compact OurPlant Pocket realises semi-automated processes and provides developers an excellent support in testing, developing and validating their processes.

The desktop machine OurPlant D1 is the basis for the seamless transition of your products

into series production.

The modular design of the OurPlant XTec guarantees adaptation to individual and rapidly changing process requirements.

Like all micro assembly machines of OurPlant, the OurPlant X3 blue is based on a modular design.

Your specific Opens Source concern hasn’t been addressed yet?

Our experts will gladly advise you.

![]() Max Körner

Max Körner

(Phone +49 36259 300 31)

![]() Christian Schiek

Christian Schiek

(Phone +49 36259 300 70)

Um dir ein optimales Erlebnis zu bieten, verwenden wir Technologien wie Cookies, um Geräteinformationen zu speichern und/oder darauf zuzugreifen. Wenn du diesen Technologien zustimmst, können wir Daten wie das Surfverhalten oder eindeutige IDs auf dieser Website verarbeiten. Wenn du deine Zustimmung nicht erteilst oder zurückziehst, können bestimmte Merkmale und Funktionen beeinträchtigt werden.